Fault pattern: Potential-induced degradation (PID) in crystalline solar modules

Potential-induced degradation occurs in thin-film modules and those made of crystalline silicon. The topic is highlighted here for crystalline modules.

What is potential-induced degradation?

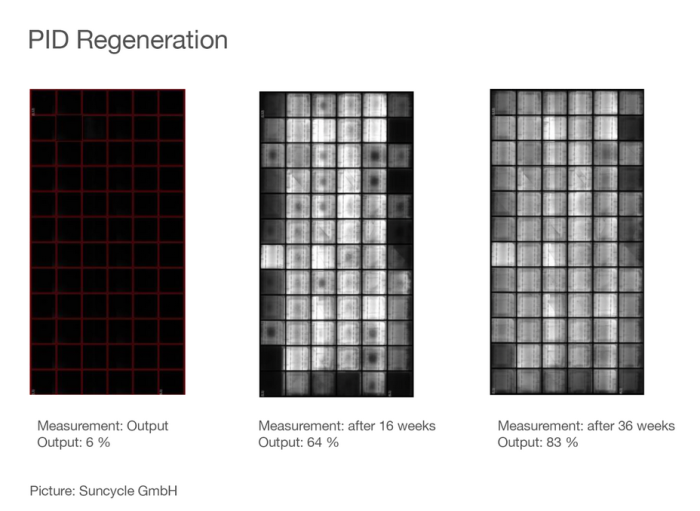

Potential Induced Degradation (PID) refers to a phenomenon that can lead to a growing decline in performance in solar modules, triggered by undesirable movements of charge carriers within the module. Three effects are distinguished: a short circuit of the p-n junction in the cell (PID-s), corrosion of the cell (PID-c), and impairment of the cell's passivation (PID-p). PID-s has been most commonly observed in crystalline modules made from p-type solar cells, with a performance decline of up to 50 percent. However, the degradation is reversible, either wholly or partially.

Which modules can be affected by PID?

PID has occurred in various types of crystalline modules: those made from n-type cells and from p-type cells, with a simpler aluminum back surface field (Al-BSF cell), as were predominantly manufactured until 2018, and with an additional dielectric layer, as is present in the now dominant PERC cells. From the outside, PID cannot be visually detected in a module.

How did PID become known?

PID was first observed in the field in 2006 with modules from Sunpower. In 2008, Evergreen Solar reported similar issues with modules that had contacts applied using a modified process. Both companies investigated the performance decline and realized that an undesirable accumulation of charge carriers occurred due to a potential difference between the module and the ground. This accumulation dissolved when the potential difference was reversed. Sunpower recommended applying a voltage of minus 1,000 volts against the ground for one hour to resolve this issue. Evergreen equipped affected installations with a box that built up a positive potential on the generator against the ground during the night.

When did PID become an issue for the entire solar industry?

While PID initially appeared to be a concern for Sunpower's back-contact high-performance cells and Evergreen's very thin string-ribbon cells, the industry recognized in 2010 that even the market-dominant modules made from p-type cells exhibited PID. This was also attributed to the increasingly higher system voltages of PV installations.

What factors influence PID?

In addition to the magnitude of the potential difference, there are four other factors that favor PID: moisture, warm air, module contamination, and diffuse light. This means that PV installations in Southern Europe and coastal areas are more frequently affected than installations in Germany away from the North and Baltic Seas. The installation that brought PID to the forefront of the entire industry was located in Mallorca.

.

What happens in the module with PID?

In p-type solar cells, positive sodium ions dissolve from the front glass. When there's a negative potential difference between the module and the ground, these ions migrate through encapsulation material and anti-reflection coating, adhere to the interface of the silicon cell, and eventually diffuse into the silicon, especially if there are tiny defects in the crystal lattice. The ions cause a short circuit between the p- and n-regions of the cell, resulting in decreased performance. Processes are slightly different in n-type silicon cells, but they also generate leakage currents due to a potential difference between the module and the ground.

What is the industry doing about PID?

Manufacturers can reduce the susceptibility of modules to PID: Glass-glass modules are less susceptible to PID. This is because moisture can diffuse through the backsheet of a glass-film module, allowing ions to dissolve from the front glass. Using encapsulation material with higher resistance makes it harder for positive ions to migrate through the material. If the silicon nitride layer on the cells has higher conductivity, the voltage across the layer in case of leakage current is lower, and the metal ions are less attracted to the cell. Through these measures, most manufacturers have managed to address the problem after 2010, according to experts' estimates. By testing according to IEC 62804 in a test laboratory, manufacturers designate their products as "PID-free" or "PID-safe".

How do installers prevent PID?

In humid and warm regions, it may not be sufficient to rely solely on "PID-safe" modules. Additional preventive measures can be taken through the type of installation. The trigger for PID is a high potential difference between the modules and the ground - meaning, the higher the system voltage of an installation, the higher the risk of PID. For p-type cells, this involves a negative potential of the modules relative to the ground; for n-type cells, it's a positive potential of the modules relative to the ground. If permitted by the inverter, the negative or positive pole of the module array can be grounded. This prevents PID from occurring. To achieve this, an inverter with a transformer must be used. For transformerless inverters, an additional device for potential reversal at night can be used, as Evergreen has employed.

What to do if a system is possibly affected by PID?

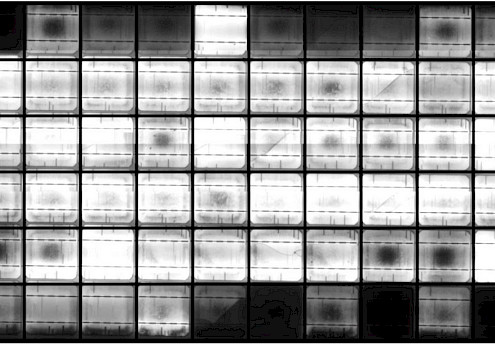

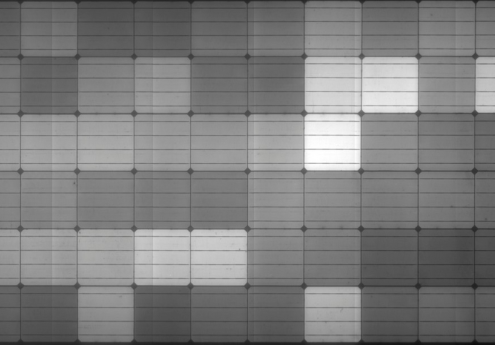

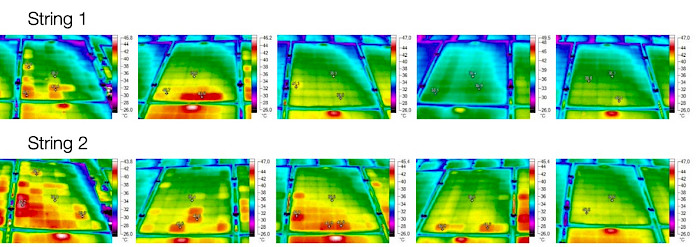

If a recently installed system shows lower yields, it should be inspected. If PID-s is present, the performance decline can be reversed, and the reversal is more complete the less advanced the degradation is. PID-s can be identified through on-site performance measurements and thermographic and/or electroluminescence imaging in the field or in a test laboratory. Retrofitting boxes for potential reversal at night or grounding the negative pole can also be done later.

Author: Ines Rutschmann

Tip if PID is suspected:

At SecondSol's test center, you can have modules tested using thermography and electroluminescence imaging. You can also find suitable PID boxes or replacement modules on the SecondSol online marketplace.