Error pattern: Microcracks and cell breakage

Where do microcracks appear?

Microcracks and cell fractures occur in crystalline wafer-based silicon solar modules. These consist of wafer-thin silicon solar cells, which are soldered together in series during manufacture to form strings and then laminated between embedding foils, a front glass and a backing foil. But there are also solar modules where glass is also used on the back. Since the solar cells are only about 0.2 millimeters thick, they are prone to hairline cracks, both during production and during transport or installation. Even after that, cell fractures can occur due to mechanical stress. These are referred to as microcracks or microcracks.

How can you detect microcracks and cell breakage in the module?

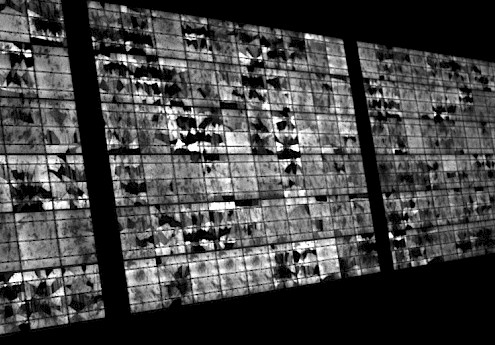

Microcracks cannot be seen with the naked eye. Even a real cell break can only be recognized if the module has been subjected to severe mechanical stress. As a rule, however, an examination using an imaging method such as thermography or electroluminescence is necessary. With thermography, temperature differences are measured on the front glass of the module. Since solar cells get warm during electricity production, this is reflected in a warmer area on the module surface. If areas of the module surface remain cold, they are inactive. This can be an indication of a cell rupture. You can see it with electroluminescence. The module is connected to a voltage source and supplied with current. This reverses the photovoltaic effect and the cells emit light. As a result, even the smallest cracks and, above all, inactive areas of the cells are visible.

What is the cause of microcracks and cell rupture?

The causes of microcracks and cell fractures are mechanical loads either during production, during transport, during installation or during operation of the solar modules. The appearance of the error can even be used to draw conclusions about the cause. Cracks that emanate from the cell connector can be caused by internal stress during the soldering process in production. These cracks are often located at the end or start point of the connector, as this is where the highest residual stress is. A cross crack can be caused by needles pressing on the wafer during production. If the cracks start from the edge of the cell, this can be an indication that a hard object has fallen on the cell. Cracks that occur during installation, for example when the module is stepped on, can also become visible in electroluminescence images. Hailstorms also cause a very specific form of cracks and cell ruptures.

What is the risk of microcracks and cell breakage?

Microcracks are not necessarily a module defect. It is important that the entire cell is still in contact with the cell grid, the busbars or the cell connector. However, such microcracks can become relevant if areas of the cell tear off the contacts. This can also happen over time. This is because thermal movements and other mechanical loads can lead to previously unproblematic microcracks becoming larger and parts of the cell then no longer having electrical contact. Changes in the microcracks can be detected by regularly checking the affected modules.

How can microcracks and cell breakage be prevented and is the defect repairable?

Microcracks that occur during production can hardly be prevented. Just as little as cracks due to weather influences such as hail. However, the module must be handled with care during transport and installation, especially if the modules have a foil backing. Also, modules may not be entered - unless the manufacturer explicitly approves this. Since small micro-cracks do not necessarily affect the performance of the module, replacement is not mandatory. However, this can be useful if the module loses excessive power compared to the other modules. A professional should be consulted beforehand. This can make the cracks and fractures in the cells visible using electroluminescence, assess the extent of the loss of performance and assess precisely whether it is worth replacing the affected modules. Above all, it is important to ensure that a replacement module fits the other panels in the string and in the system. You can find suitable replacement modules on the SecondSol online marketplace.