Error pattern: Light-Induced Degradation (LID) in crystalline modules

The phenomenon of LID has been known and extensively researched in monocrystalline solar modules since the 1970s. Technically, it is considered solved. Standard modules may exhibit around 0.5 percent light-induced degradation, but it should not exceed this. Manufacturers must take this performance loss into account when specifying the nominal power.

With which modules can a higher light-induced degradation occur?

Monocrystalline modules made from p-type silicon can exhibit light-induced degradation (LID) of more than one percent. In p-type silicon (where "p" stands for positive), foreign atoms with one fewer outer electron than silicon are initially introduced into the crystal lattice, creating an excess of positive electron holes. For a long time, boron was predominantly used as this foreign atom (B-LID).

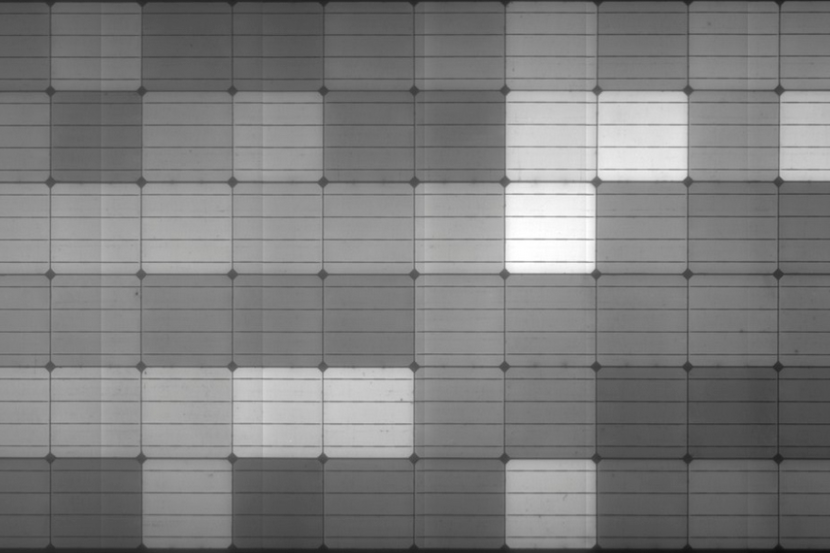

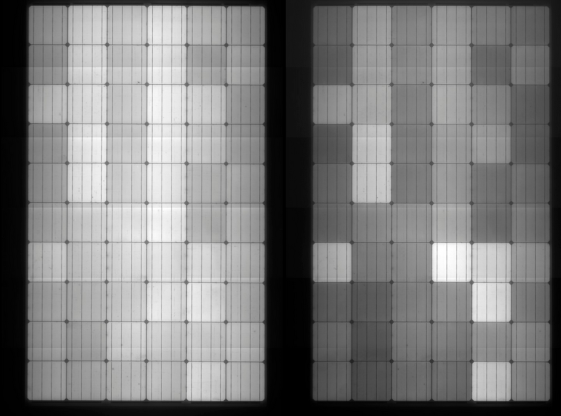

Source: Fraunhofer CSP - Electroluminescence images of Mono-6 M2 before and after the LeTID test.

What happens in the case of B-LID?

During light-induced degradation, the power output of a monocrystalline module irreversibly decreases in the first few hours of exposure to light. This is mainly due to the formation of so-called boron-oxygen complexes within the silicon lattice. Oxygen accumulates in small amounts during the pulling of ingots in silicon. When boron is introduced during wafer manufacturing (in the case of p-type silicon), it can combine with oxygen to form a complex.

This complex creates its own energy level and traps charge carriers that are lost for electricity production. As a result, the efficiency of the module decreases. Metals such as iron, which are present in the silicon lattice, can also combine with boron and cause LID, but to a lesser extent than boron-oxygen complexes.

How can higher light-induced degradation in production be avoided?

There are two ways to avoid or minimize light-induced degradation. The phenomenon (B-LID) does not occur when using solar cells made of n-type silicon. For this, the wafers are initially doped with an element that has one more outer electron than silicon, typically phosphorus. Alternatively, when using p-type silicon, a different element than boron can be introduced into the silicon. Gallium has proven effective, as light-induced degradation is then significantly reduced. Nowadays, p-type solar cells typically contain gallium instead of boron as a standard practice.

How much can the module yield decrease due to LID?

When the first photovoltaic boom in Germany began around 2005, the effects of LID were most pronounced. Solar silicon was purchased based on availability, even if it was of lower quality. If the starting material contains a high proportion of oxygen, light-induced degradation of monocrystalline p-type cells can range from three to seven percent. This stage has long since passed. However, even with good solar silicon, the power output still decreases by around two percent due to LID when p-type solar cells are doped with boron. If boron-oxygen complexes cannot form or form only to a limited extent, degradation due to other effects still amounts to about 0.5 percent. The respective reduction in power output should be considered by a manufacturer when specifying the nominal power on the nameplate - as required by DIN EN 50380. This means that the nominal power stated on the nameplate should still be achievable by a module after the first few days outdoors.

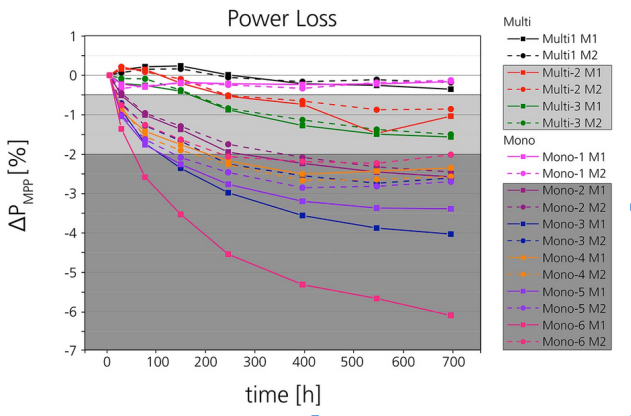

Source: Fraunhofer CSP - STC power drop during the LeTID test.

How can LID be recognized in installed PV systems?

If a recently installed system shows lower yields, it should be inspected. If LID is present, it initially manifests as a decrease in the performance of the PV system. Additionally, affected solar cells appear darker than high-performance cells, often displaying a checkerboard pattern. Visual inspection and on-site performance measurements can be helpful as initial steps. LID can also be detected through electroluminescence imaging.

Author: Ines Rutschmann

Tip if LID is suspected:

You can have electroluminescence recordings of modules carried out at the SecondSol test center. You can find suitable replacement modules on theSecondSol online marketplace.