Error pattern: Hotspot

Where do hotspots occur?

Crystalline, wafer-based silicon solar modules consist of wafer-thin silicon solar cells that are soldered together in series to form strings during production. As a result, the electricity produced flows through all the solar cells in the string to the arrester. If a cell or part of a cell is not active, i.e. no longer produces electricity, the internal resistance of this cell or part of a cell increases. However, the current of the other cells continues to be pushed through the inactive cell. The high ohmic resistance results in a power loss and this is given off to the environment in the form of heat. That is why such places are called hotspots. This can also affect entire modules.

How can you identify hotspots in the module?

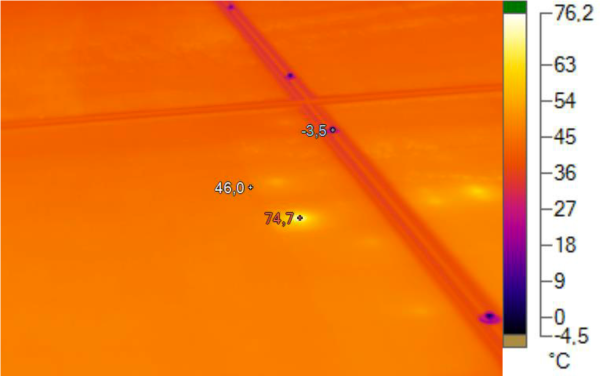

The first sign is a drop in the plant's performance and electricity yield. There can be several causes, wherefore a thermographic examination is recommended. A special camera is used to record temperature differences on the module surface while the solar system is producing electricity. In order to generate sufficiently high-temperature differences, good solar radiation is necessary for a thermographic examination. The temperature differences on the module surface are displayed in color in the thermographic camera. This makes it easy to see where hotspots are occurring in the solar cells.

What is the cause of hotspots?

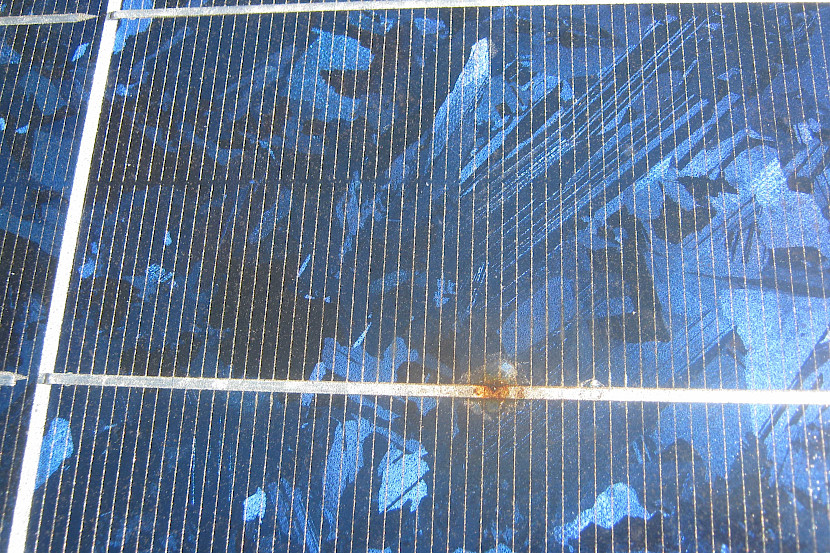

Hotspots are usually caused by local shadowing. A tree that partially shades a solar module can trigger a hotspot just as much as a leaf lying on the solar module. Bird droppings and other dirt on the module surface are also frequent causes of hotspots. However, hotspots can also occur due to manufacturing defects such as bad solder joints or microcracks.

What is the risk of a hotspot?

Since the temperature of the modules can become very high locally due to the hotspot, there is a real risk of fire. So it is possible that a dry branch or similar material that is close to the hotspot could ignite. Therefore, hotspots should be taken seriously. However, the solar modules contain a safety device in the form of bypass diodes. If the voltage in one cell of the string becomes negative and as a result becomes an ohmic resistance, the current of the other cells of the module is conducted through this diode. As a result, the current is not only routed around the affected cell, but around the entire cell string. Although this avoids the hotspot, it also reduces the performance of the module and thus of the entire module string. The result is a reduction in the yield of the solar system.

How can you prevent hotspots and is the error repairable?

Some causes of hotspots are avoidable, such as those caused by shading. For this reason, the system operator or a service provider commissioned by him should take a look at the system more often. With such a visual inspection, dirt and partial shading can be easily recognized. In addition, regular cleaning of the generator is a worthwhile investment, especially since the yields generally increase. This is especially true for systems installed in dusty locations or near trees. But a look at the surrounding vegetation can also be worthwhile. Because within 20 or more years of operation of the photovoltaic systems, the shading situation can change due to vegetation.

If hotspots occur due to a production error, the affected module may need to be replaced. The bypass diodes installed in the module ensure that current is conducted through the inactive cell areas. But if this safety device also fails, the affected area can become very hot. When replacing the module in question, it is important to ensure that a replacement module fits the other panels in the string and in the system. You can find suitable replacement modules on the SecondSol online marketplace.