Error pattern: Glass breakage

Where do glass breakages occur?

Solar modules consist of a front glass and the solar cells, which are embedded between two films, or various semiconductor layers, which are applied to this front glass. The back consists of either a special film or a second glass. As glass is very hard but also very brittle, it can break if handled incorrectly or if it is overloaded. This can affect the entire front of the module. In the case of double glass modules, the back can also break, although this is less common.

How can you recognise glass breakage on the module?

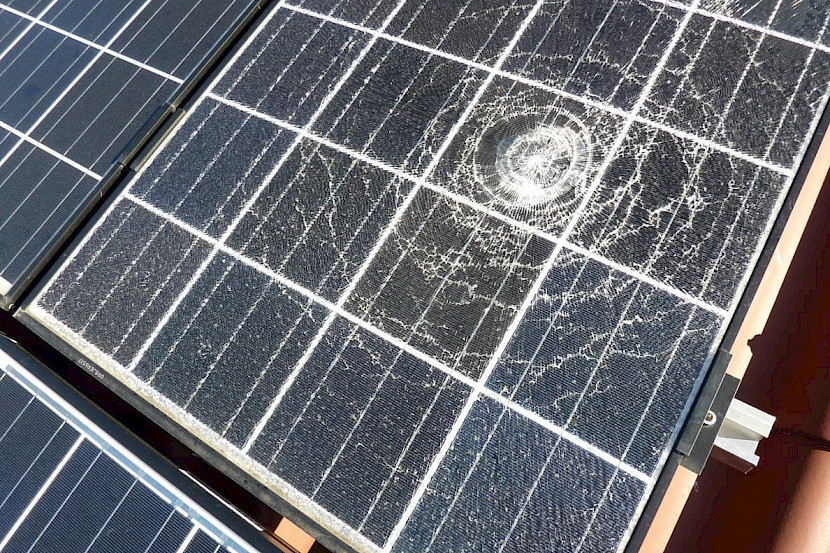

Usually, glass breakages are very noticeable. However, they can easily be overlooked if they occur at the edge directly at the transition to the module frame or around the module clamps. During the inspection, you should check carefully whether these areas are also free of breakages. If the glass breakage occurs in other areas of the module surface, they can be recognised by the typical cracks.

What is the cause of glass breakage?

The cause of glass breakage is usually mechanical overload. These can occur in different ways. With unframed modules in particular, they can be caused by an installation error, for example if the wrong, too short or too narrow module clamps have been used. Clamping in the wrong place or tightening the clamp screws too tightly can also lead to glass breakage in these modules. Therefore, when installing unframed modules, care should be taken to use clamps that are certified by the module manufacturers and to position and tighten them as precisely as possible according to the manufacturer's specifications.

However, incorrect handling of unframed modules can also lead to minor glass damage, for example if the module is placed carelessly on a hard surface before installation. Such small cracks can become larger over time due to fluctuations in the outside and module temperatures.

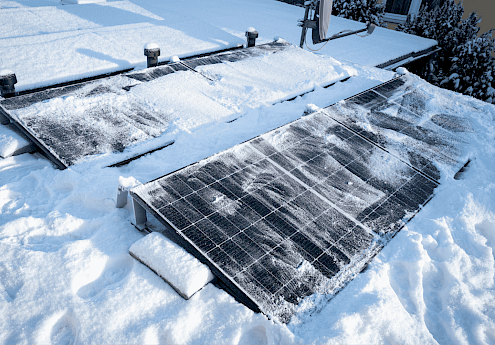

Mechanical loads during operation of the PV system can also lead to glass breakage - such as excessive snow or wind loads. Snow loads in particular can be a problem here. It is true that the modules are designed for certain snow loads and have been tested accordingly. However, the tests only cover permanent loads. Short-term overloads are not taken into account here. In addition, the snow load is distributed very differently on inclined modules. This is because the snow slides to the eaves side of the module, where the load is correspondingly higher.

Hail is a frequent cause of glass breakage. The modules can generally withstand hailstones. However, the IEC 6121 standard only contains a standard test with hailstones 2.5 cm in diameter hitting the module surface at 23 m/s. This is almost 83 km/h. That is almost 83 km/h. However, if the hailstones are larger, it is quite possible that the module glass will be damaged.

What is the danger if the glass breaks?

Glass breakage can lead to a loss of performance over time. This is because moisture penetrates the module through the cracks, which in turn leads to corrosion of the cells and the electrical circuitry. However, electrical safety is also an issue here. This is because breaking the module glass can reduce the insulation resistance, meaning that the module can pose a danger, especially in damp weather. Glass breakage is also often a source of a hotspot, which in turn can lead to the module overheating.

How can glass breakage be prevented and is the fault repairable?

To prevent glass breakage, any mechanical overloading must be avoided. This starts with the transport of the modules and handling by the installers. If it is already clear that the system will be built in a region with a high snow load or many hailstorms, appropriately designed modules should be used. Some manufacturers have panels in their range that can withstand higher loads. Many mounting system manufacturers also offer additional mechanical support solutions for heavily loaded modules.

However, the system operator cannot do anything against fast-flying large hailstones, branches or stones. They can only check the system after the storm or hail event to see if any glass breakage is visible. If this is the case, it may be advisable to replace the module. Repair is generally not possible, as the module glass is firmly bonded to the embedding foils and the solar cells. When replacing the module in question, it is particularly important to ensure that the replacement module matches the other panels in the string and in the system. You can find suitable replacement modules on the SecondSol online marketplace.