Polycrystalline solar cells: Part of the most commonly used PV modules

Polycrystalline solar modules are currently the most commonly installed photovoltaic modules worldwide. In Germany, 80 percent of the solar modules consist of polycrystalline solar cells. In recent years, the technology has made great advances thanks to intensive research. At the same time, due to the great competition and the improvement of the manufacturing process, the prices steadily fell. Global market share has increased by an average of 44 percent each year since the turn of the millennium, while PV module prices have fallen by 90 percent. This is due to the fact that, thanks to improved production conditions, only half as much material is used as it was twenty years ago. Further optimization of the manufacturing processes is expected for the future.

The manufacture of polycrystalline solar cells

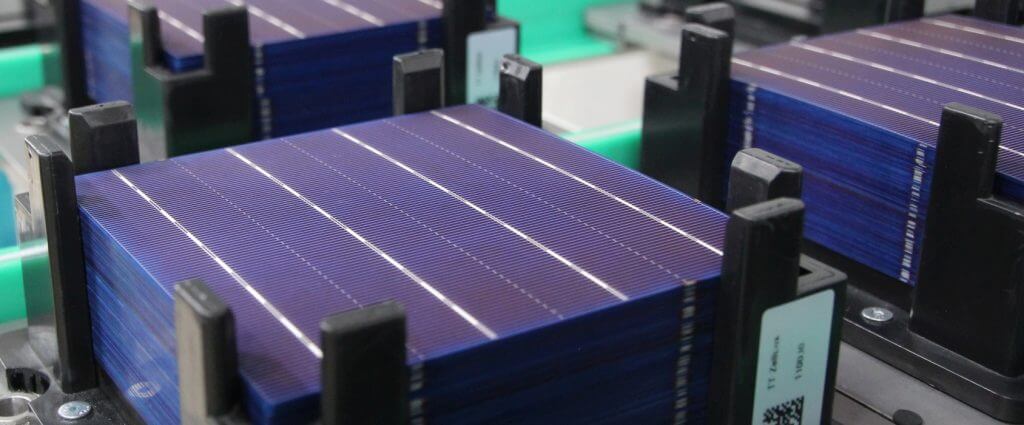

Pure silicon is required for the production of photovoltaic modules. Polycrystalline solar cells use less pure silicon than monocrystalline solar cells. In the case of polycrystalline solar cells, the silicon is doped with boron atoms. The simplest method is the casting method. To do this, the silicon is heated in a vacuum until it reaches a temperature of around 1500 degrees Celsius. A silicon block measuring 40 cm x 40 cm x 30 cm is cast in a heat-resistant graphite mold. After it has cooled down, columns, so-called ingolts, and then flat, 0.3 mm thin slices, so-called wafers, are cut from it.

Image source: Astronergy

A more complicated and expensive method is the Bridgeman method. Here, too, silicon is melted in a crucible at high temperatures. In contrast to the ingot casting process, however, the melt does not cool down in an additional container, but remains in the same container. If the induction heating moves in an upward direction, the silicon solidifies from bottom to top. After it has solidified, the material is further processed as in the ingot casting process.

Polycrystalline solar modules: affordable cutting-edge technology

Polycrystalline solar modules currently dominate the market. This is because of the many benefits they exhibit. The efficiency of polycrystalline modules is 10 - 18%. In contrast, a monocrystalline solar module achieves efficiencies of up to 22 percent. This is because there are losses between the areas of different orientation of the crystals. As a result, the efficiency decreases in contrast to monocrystalline solar cells. On the other hand, the production of polycrystalline solar cells is much easier than that of monocrystalline cells. As a result, they are considerably cheaper and, despite the lower power generated, have a better price-performance ratio.

On the other hand, their efficiency is significantly higher than that of the very inexpensive and light thin-film modules, which achieve a maximum efficiency of 10 percent. In addition, they require little maintenance and are less prone to malfunctions.

Features and Maintenance

Polycrystalline modules are mostly blue and sometimes glitter in the sunlight due to the irregular crystal structure. The crystals do not all point in the same direction - The disordered crystalline structure is evident on the surface.

In the module, the solar cells lie directly next to each other and are square. Sometimes there are manufacturing-related differences between the individual cells of a module.

The life expectancy of a module is around 30 years. The production of polycrystalline solar modules requires less energy than that of monocrystalline ones. As a result, they have a better ecological balance overall.

Areas of application of polycrystalline solar cells

A disadvantage of polycrystalline solar cells is the loss of performance when the light is weak or at high temperatures. Compared to monocrystalline solar cells, they are less efficient. Ideally, modules made of polycrystalline solar cells are therefore installed on large roof areas that face south. In this way, the difference in performance compared to monocrystalline modules can be compensated.

Buy polycrystalline solar modules

Depending on the budget and the area available, a module made of polycrystalline solar cells is the right photovoltaic solution for your own home or solar park. Polycrystalline modules are a comparatively inexpensive, but at the same time robust technology. In the Internet portal SecondSol, which specializes in photovoltaics, you can compare prices and products and find the right provider.