Quality, not quantity: the importance of solar module inspection

Why is quality assurance so important?

High-quality solar modules are crucial to ensure the longevity and efficiency of installations. Especially for open-field installations, which are often designed for an operating period of 20 years or more, quality and reliability play a key role. VDE SPEC 90038-3 provides a structured framework to standardize the quality assurance of solar modules. It addresses the following main points:

- Standardization of communication between manufacturers and customers

- The specification defines uniform requirements for modules made of crystalline silicon, which are used in most ground-mounted systems.

- This facilitates the purchasing process by providing clear guidelines for quality and inspections that can be contractually agreed.

- Measures for quality assurance in the production process

- Audits: Systematic inspection of production facilities, processes and quality management systems by specialized auditors.

- Production monitoring: ongoing control of manufacturing processes to ensure that the manufacturer's internal quality standards are met.

- Pre-shipment inspections: random testing of finished modules before shipment, including performance measurement, electroluminescence imaging, visual inspection and insulation testing.

- Loading inspections: monitoring of loading and ensuring that transport documents are completed correctly.

- Standardization of testing and acceptance processes

- The ISO 2859-1 standard is used to determine sample sizes for inspections. These ensure that tests are carried out representatively and efficiently, without consuming excessive resources.

- Significance for the solar industry

- The specification improves the reliability and performance of solar modules while strengthening trust between manufacturers and customers.

- It provides a basis for reducing complaints, minimizing failures and saving costs in the long term.

The VDE SPEC 90038-3 is an important step towards standardized quality assurance in the solar industry. It is not only a tool for ensuring product quality, but also a means of simplifying processes and meeting the growing demands of the market.

What does a pre-shipment inspection include?

Pre-shipment inspections (PSI) are a crucial part of quality assurance. Typical tests include:

- Performance measurement: checking whether the modules deliver the promised output, e.g. by measuring the open-circuit voltage (Voc) and the short-circuit current (Isc).

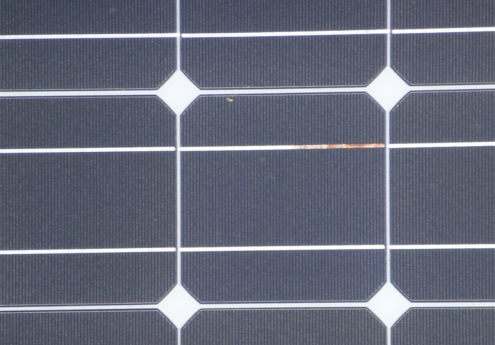

- Electroluminescence imaging (EL): special images make invisible defects such as micro-cracks visible.

- Visual inspection: Identification of external damage such as glass breakage, damaged frames or incorrect labeling.

- Insulation test: Ensuring that the electrical resistance between active parts and the frame is sufficient to avoid safety issues.

SecondSol tip: These tests should not only be carried out before shipment, but also again on a random sample when they arrive in Europe / before installation, in order to control the complete process chain.

How is the sample size determined?

The ISO 2859-1 standard defines how a representative sample is selected from a large lot size. Typically, the “General Inspection Level I” is used. The sample size increases with the lot size, but not proportionally. Examples:

- 501-1200 modules: sample of 80 modules

- 1201-3200 modules: sample of 125 modules

- 3201-10,000 modules: sample of 200 modules

- 10,001-35,000 modules: sample of 315 modules

- 35,001-150,000 modules: sample of 500 modules

- 150,001-500,000 modules: sample of 800 modules

- >500,000 modules: maximum sample of 1250 modules

Why is this important for solar park operators?

Module inspections are particularly important for solar park operators because they:

- avoid complaints: defective modules can be identified and sorted out at an early stage.

- minimize failures: high-quality modules ensure maximum uptime.

- maximize investment returns: efficient and reliable modules increase yields.

PV module testing at the SecondSol test center

Our SecondSol test center offers you the opportunity to have your modules tested independently and flexibly – before shipment or installation. We help you ensure the quality and reliability of your solar modules.

Find out more and contact us here:

SecondSol test center