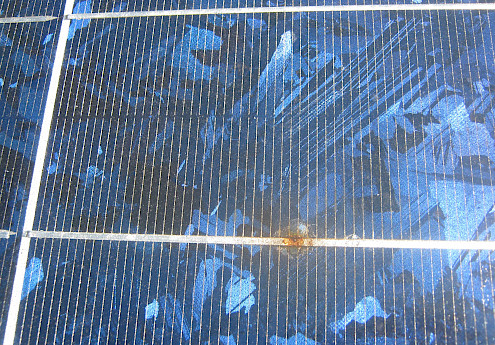

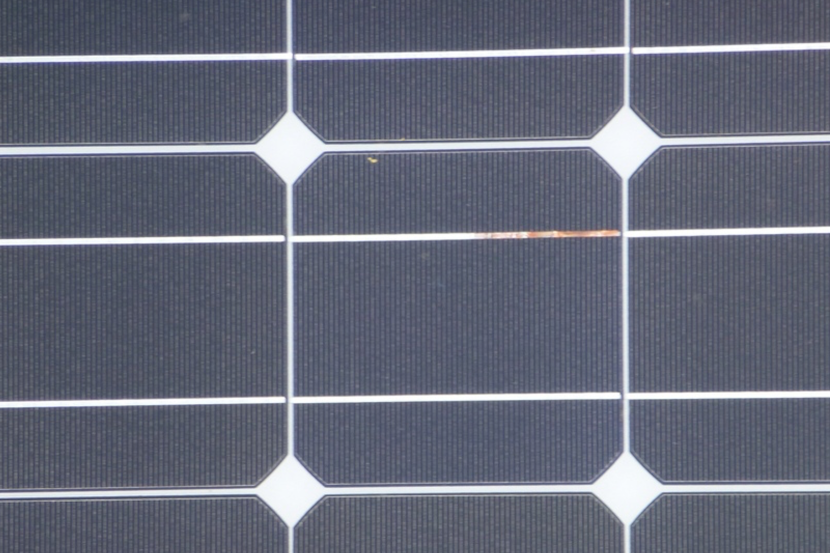

Error pattern: Corroded solder joints

Where do solder joints corrode?

Crystalline solar modules consist of individual solar cells that are connected in series using tinned copper cell connectors. Depending on the cell size and development, 2 to over 14 such connectors are currently processed per cell. Typically, 3 double cell strings with 20 to 24 cells are embedded in a solar module. These individual cell strings are soldered to a so-called cross-connector in order to conduct the current to the junction box and to the bypass diodes.

How can you identify corroded connectors and solder joints in the solar module?

Corroded solder joints are easily visible to the naked eye. They are evident from a typical discoloration of the areas where the cell connectors are soldered to the cross connector.

What is the cause of corroded solder joints, cell connectors and cross-connectors?

Corrosion usually occurs when moisture penetrates the PV module. On the one hand, this can be a normal aging phenomenon and dependent on the location. On the other hand, corrosion can in turn indicate improper processing during production of the PV module or a defective backing film.

What is the danger of corroded solder joints?

Corrosion of soldered connectors can increase electrical resistance and also increase the risk of arcing. The increased resistance of the photovoltaic module can reduce performance and energy yield. If the cell connection is completely broken on a cell, this part of the module fails completely and is removed from the system string by means of the bypass diodes. In relation to the module, a third of the power is lost. As a rule, such a defect is not limited to one cell. In this way, further soldering points can corrode, which can gradually lead to the complete failure of the photovoltaic module and the PV system.

How can one prevent corroded solder joints and is the fault repairable?

The operator of the solar system can hardly prevent or stop corrosion. It is not certain whether additional sealing of the rear film or the module assembly will solve the problem. After all, the moisture is already in the module. A specialist can use the power losses to assess whether replacing the module is advisable or even necessary. The system operator should ensure that any replacement module electrically matches the other modules in the string. You can find suitable replacement modules on the SecondSol online marketplace.